October Update

Despite my perpetual feelings of never doing or making enough, I have done and made quite a bit this past month. Maybe this blog will help me see the progress from an objective perspective.

I’m actually settled here now — I’m a legal California resident, got a supplementary job in the kitchen of the bar & grill half a mile down the road (that I’ll potentially be quitting soon for a ceramics studio gig.. fingers crossed), and have a kinda-sorta-daily-routine blossoming. More importantly, I feel I’ve been really thriving here. My cohort is all good people. There’s no drama or weird energy, and I have faith it’ll stay that way. Aside from being sick for nearly 3 weeks straight and now being covered in everlasting poison oak/oak mite welts (I’m fine tho I promise) (oh I also have been stung by wasps 5 separate times lol) — I am physically healthy. I’ve gotten faster at biking up and down the mountain, and wholeheartedly enjoy working up a sweat tossing and moving wood.

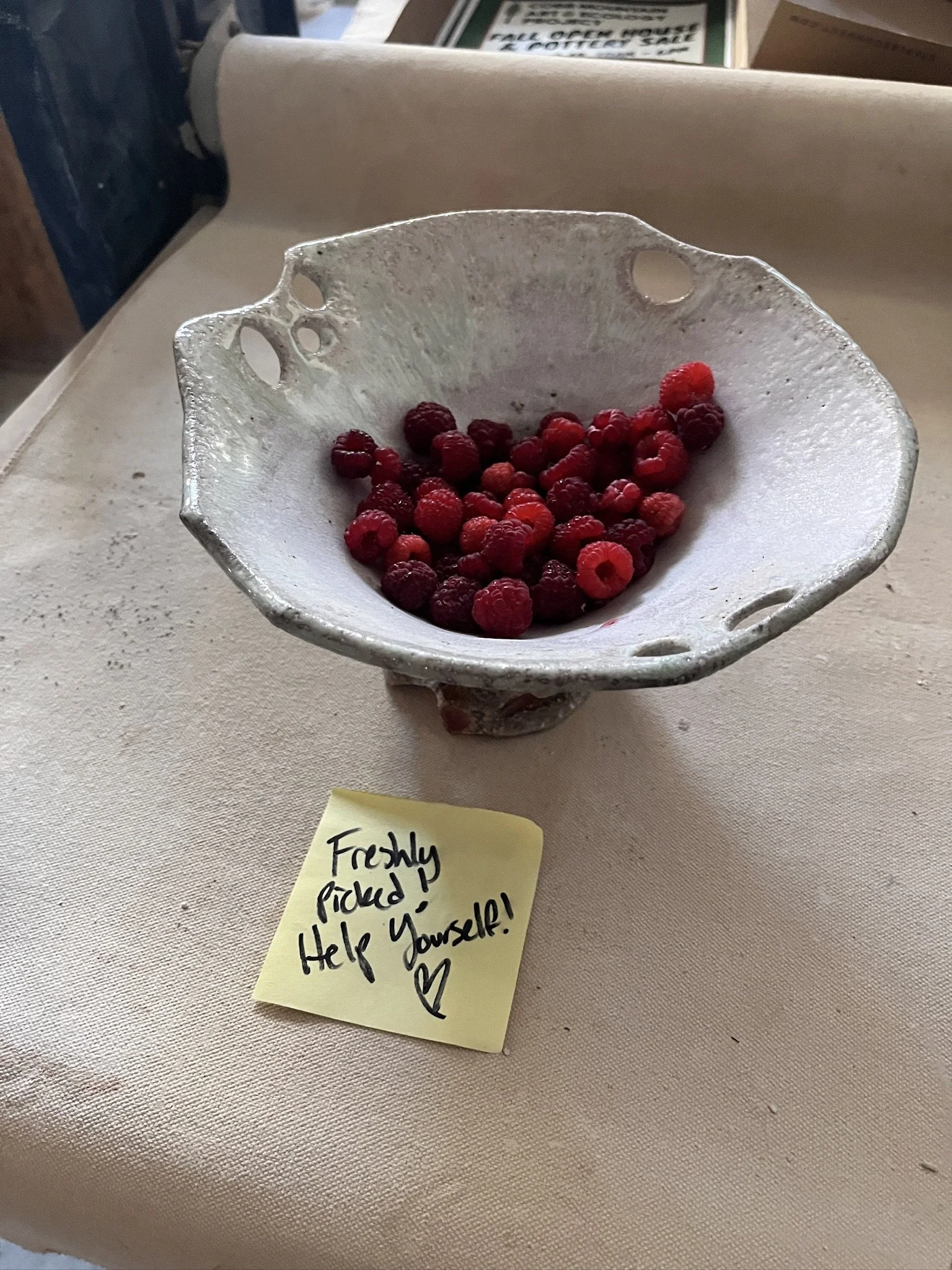

I’ve got a doctor who I don’t have to wait 4 months to see, and even had food stamps for a while before the government shut down and we all lost benefits for the foreseeable future. I’ve been eating and cooking lots of good food, loving communal meals and fresh veggies and fruits from Scott’s garden and local farmer’s markets. Syd (another woodfire resident who lives with me) is very into baking and bakes at least 2-3 new desserts for all of us each week. It’s pretty epic. Also the kitchen is directly above mine and Casey’s studio, so we get to smell whatever’s being cooked (which most of the time is very welcomed).

The weather’s been beautiful - a couple rainy days interspersed with mainly sunny, perfectly warm ones. I really like working outside when I can.

I spent the past 5 weeks making functional work for the resident soda firing leading up to Cobb’s Fall Open House sale. Aside from the batch of slipcast cups made with Laguna “Speckstone” casting slip, I was working with the Standard Clay 153 stoneware, the Beck Porcelaneous stoneware I brought with me + ~3% playground sand I wedged in, and some clay called "Helmer Wood” from East Bay Clay + 3% playground sand.

Casey taught me how to make terra sigillata! After making a batch with XX Saggar together, I made my own with helmer kaolin and OM4 ball clay + titanium. I was curious to see how the sigs from lighter clays would look on my iron-rich stoneware and the brown casting slip.

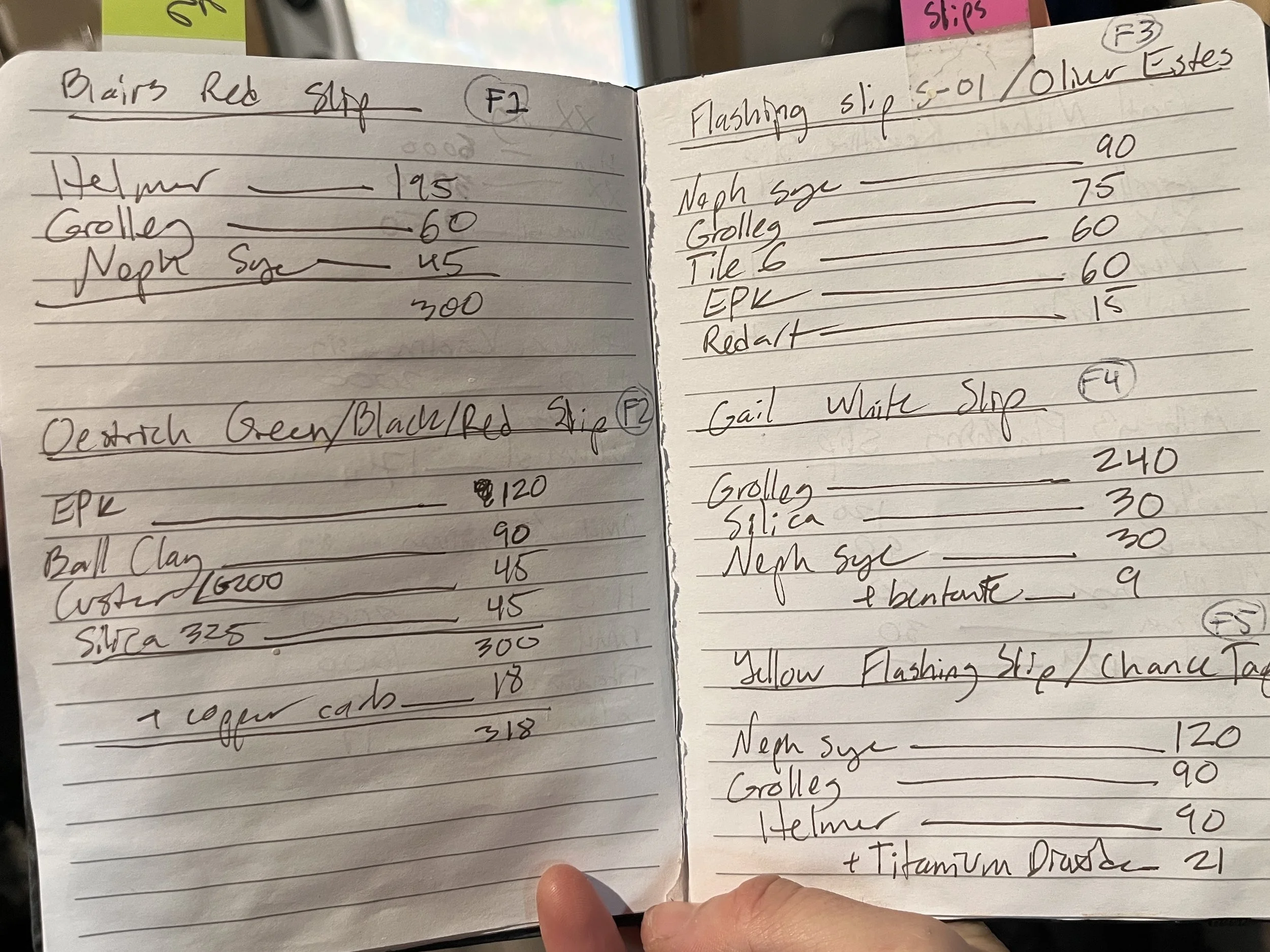

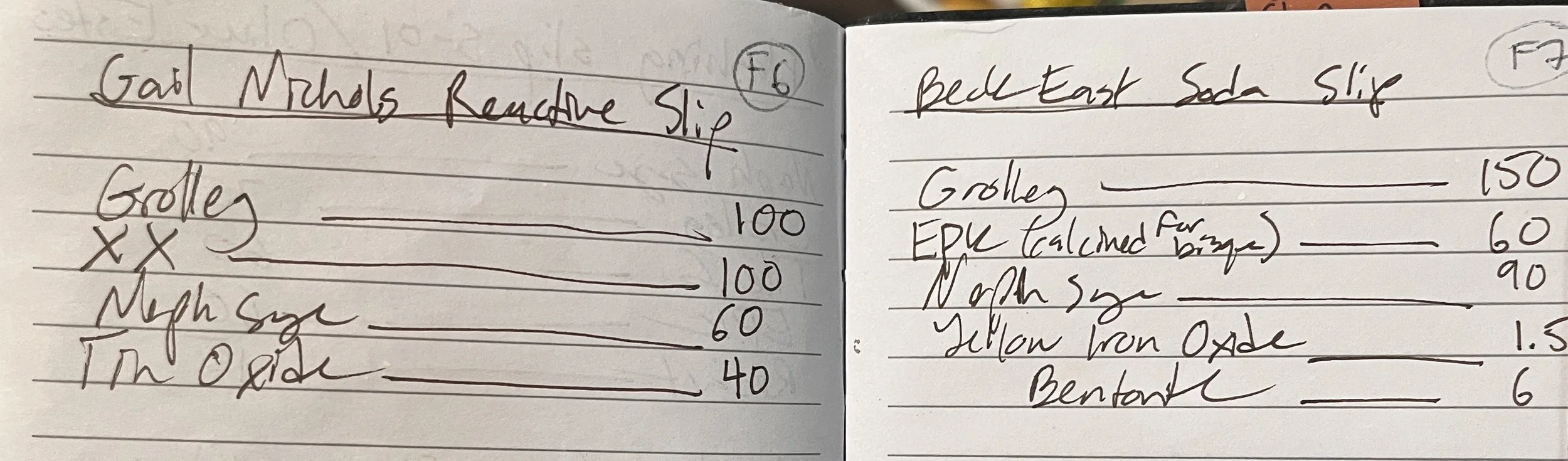

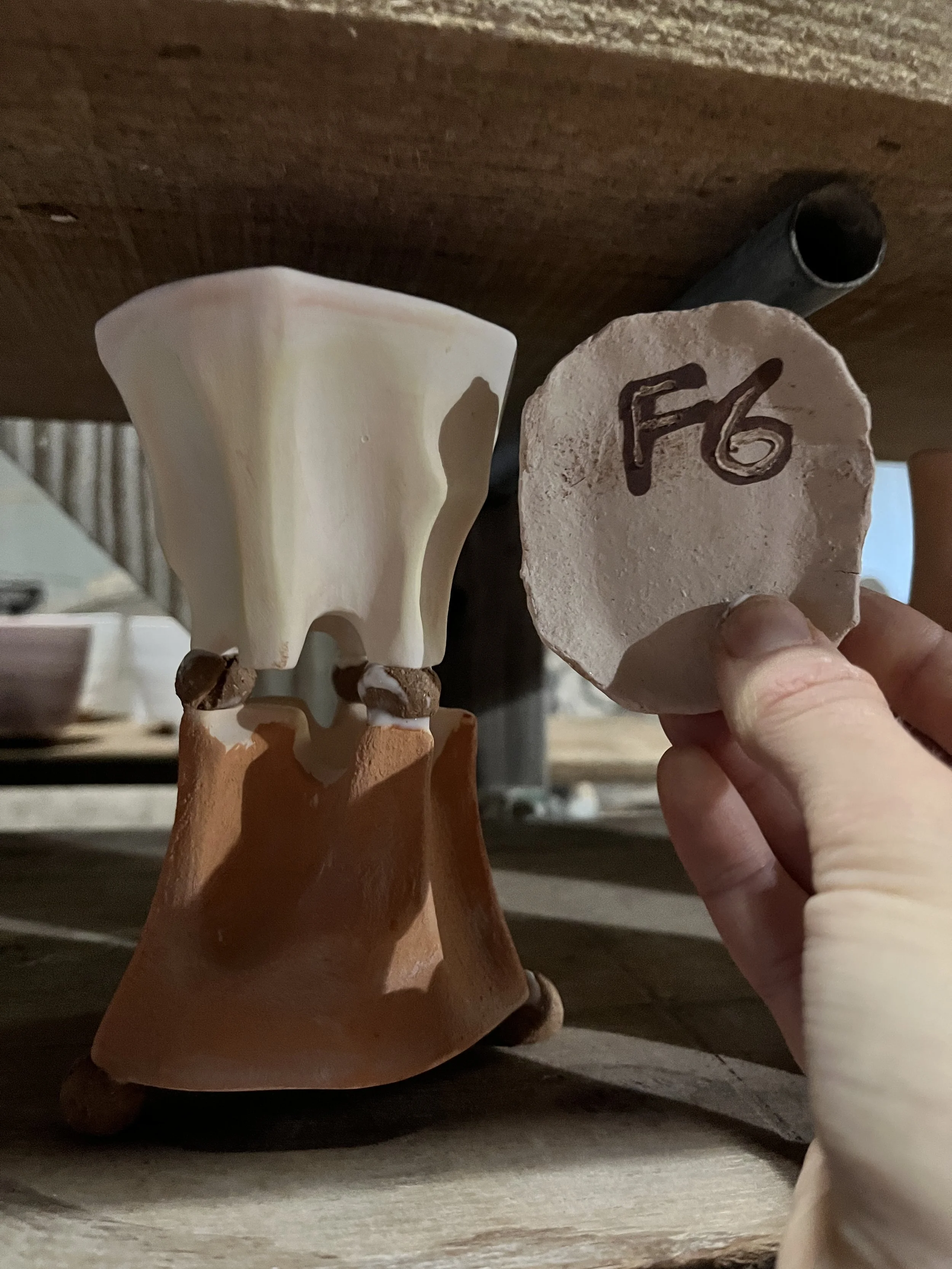

I also mixed up test batches of 6 different flashing slips that I tried on the slipcast cups + Helmer Wood test tiles. I knew it would be hard to determine consistent results from this firing alone, but that I’d get some good starting information at least.

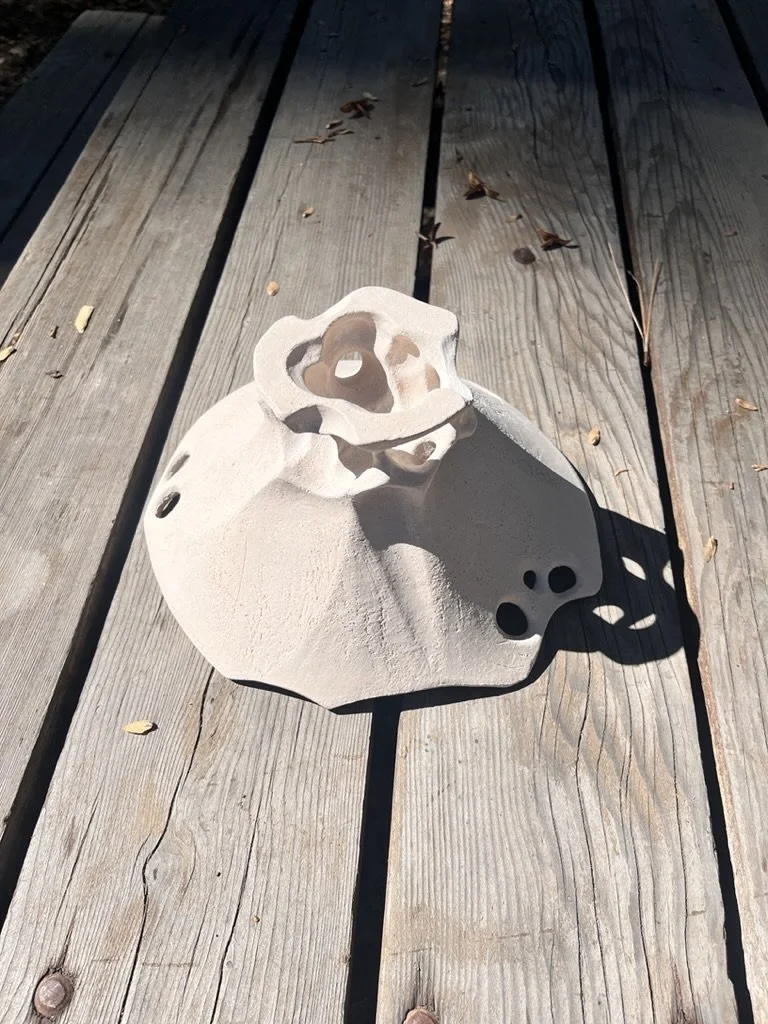

I am still searching for a simple, cost effective sculpture stoneware that I can mix myself. I bought some raw materials of my own to make the flashing slips and mixed up a sample batch of this “XX Saggar Stoneware” from HP Bloomer’s Glazy page - that he got from Jason Hess. I added ~5% playground sand.

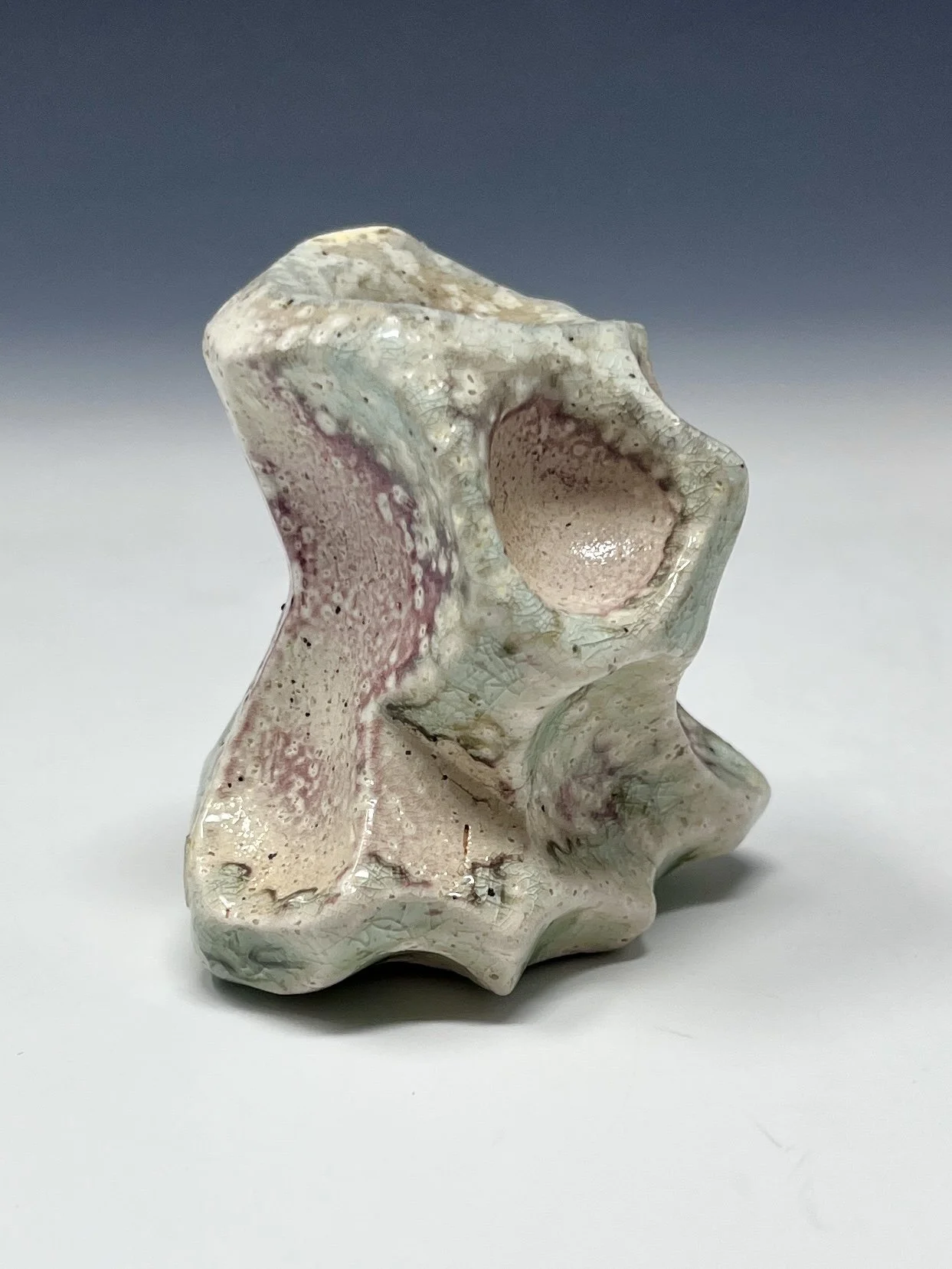

I liked the color and soda effects on this clay, but I don’t think it fully vitrified at cone 10. Planning to return to this once I get through the remaining sculpture clay I brought with me.

Casey spearheaded the load and firing. This is a crossdraft kiln similar to the one at IUS but with Venturi burners, which I’d never fired with before. It has a firebox for stoking wood, too. It shares a chimney with the train kiln. Casey started candling around dusk on loading day and it was around ^08 when I checked it at 5am the next morning. ^7 was bending around 9am, and that’s when we started introducing soda in the form of burritos through the ports above the burners.

Soon after we began spraying, which continued through the early afternoon. We only sprayed straight through the ports above the burners - not directly on any pieces. We did 3400g of soda total with the burritos/saturated solution combined. Casey let the soda soak for 2-ish hours, stoking a bit of wood here and there for a light reduction. The firing was completed in 24 hours, maybe a little under, which is pretty efficient for that kiln. Casey did things much differently than I have been the past few years I’ve been soda firing - I’m excited to implement what I learned from him in future firings here.

I had fun tumble stacking my little forms and putting them in risky places. I put a mug on the bagwall that got absolutely obliterated with soda and one of the XX Saggar Stoneware test pieces (a little candle holder) in the flue that got some interesting pink flashing. And many beautiful soda drips all around. High risk, high reward!

To my surprise, pretty much everything turned out favorable for me in this firing, which is a definite first for any atmospheric firing I’ve had work in. I owe much of this to Casey’s stacking and firing schedule. But I also didn’t expect the casting slip to turn out so bright with it being a medium brown in the green/bisque stage. Those cups got some absolutely killer flashing and crystallizations.

Casey fires in a lighter reduction atmosphere than I am accustomed to, but I didn’t mind the brighter palette on my stoneware. Nothing really got that ugly oxidized beige/yellow look - still lots of vibrant red/orange flashing on my iron rich claybodies.

I have no idea how that tiny bowl got fused with that orange cup because they weren’t even next to each other in the kiln, but I am keeping them together forever.

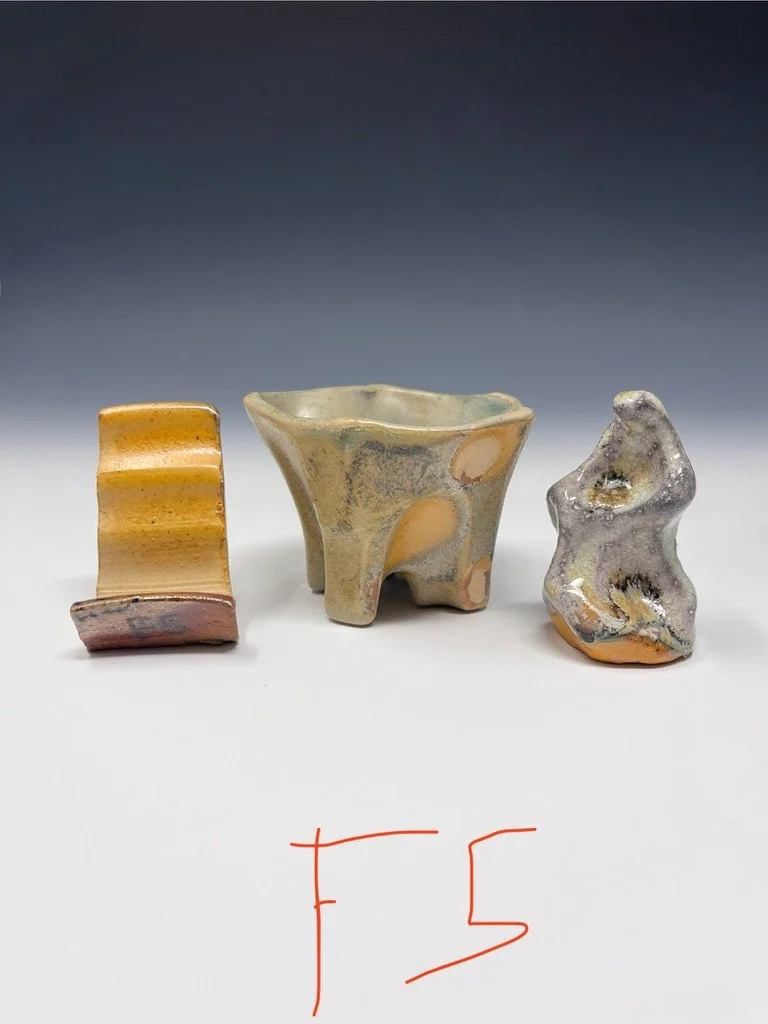

Here’s some results from my flashing slip/sig tests…

XX Saggar Stoneware + some wild clay tests…

Oh yeah — and Casey gave me some of his clay in exchange for some of my stoneware that he wanted to test some stuff on! It’s got such weird and unique flashing tendencies. He hasn’t released the recipe yet, but I love the way it looks with my forms and hope he’ll maybe trade me for more of it in the future.

I was pretty satisfied with the amount of sellable work I had for the open house. I made a bunch of rock magnets that did not really sell at all but I’m glad to have them for the future. It was cool seeing which pieces of mine people were drawn to, and receiving feedback on my work. Very kind words from many folks - and lots of cool people (and friends!!) who trekked up for the sale.

story sale aftermath minus 1 larger box

I only made a handful of sales at the actual event, but I did a story sale on my Instagram the following day and sold everything. I am still in partial disbelief that there are random strangers from all over the country (+ Canada and Singapore) interested in and willing to pay high prices for my work, but I am very, very grateful, regardless.

In other news, we’ve been moving a lot of manzanita wood down the mountain in preparation for a manzanita-dominent train kiln firing this coming spring. It’s easily the coolest looking (and sounding) wood that we harvest, so that’s been a lot of fun. Except for when the logs get stuck to your work gloves and bonk you in the head when you try to throw them uphill.

Working on the property has been really enjoyable for me. Especially when dogs are involved and when the forest leaves me tips in the form of sun-bleached dollar bills.

:)