Week 15 - Processing Found Materials, Mostly

This week, I’ve been busy processing and testing all the materials I collected on my road trip. Using information from the first round of fusion buttons I stuck in the cone 10 last week, I decided to test some of the soils/clays with about 50% wood ash added and got some really intriguing results. The most exciting results came from the clay and soil that I collected along the highway in western Utah. I’d already fired the clay in the Cobb wood fire so knew that it completely melted at cone 10. I’ve yet to test it at lower temps but have a fusion button ready for whenever the next cone 6 is fired off. I’m mainly interested in using it as a high fire glaze, though. The unprocessed tests came out great, as did the recent ones that I slaked through a fine mesh sieve. It’s a beautiful transparent green that is opacified and lightened with the added wood ash. The Utah soil is a slightly lighter and more opaque glittery green. I want to find out what the green color is coming from in these samples.

left: processed clay slip + ~50% wood ash, middle: unprocessed clay slip, right: processed clay slip

left: processed soil slip + ~50% wood ash, middle: processed soil slip, right: unprocessed soil

I was very surprised by how the added wood ash brought out this beautiful rutile blue effect in my soil sample from northwestern Arizona.

left: processed soil slip + ~50% wood ash, middle: processed soil slip, right: unprocessed soil

Another pleasant surprise came from the blue soil I collected in northwestern Arizona. I was blown away by these results!

I ran a couple slip tests with some clays I collected around Azule in North Carolina. The tiles on the left are the bare clay slip, the right have about 50% wood ash added.

I finally got around to testing the clay I collected behind my dad’s house in Greer, South Carolina. It’s pretty crumbly and short to work with, but it’s got what I believe to be specks of mica/muscovite that make it sparkly in the greenware stage. It is pretty refractory and doesn’t melt at cone 10, but the mica burnt out. So it might be more suitable as a low/mid-fire body with some added flux. I was pretty excited by this discovery - I was hoping to find some micacious clay in New Mexico but didn’t know where to look/didn’t have enough time, and little did I know that I had already some from a way more accessible source!

All these tests call for more test tiles. So I threw some more (plus a couple bowls, just cause, and two vases that I hope to alter/carve for the wood firing in a couple weeks. But realistically I think my brain was just overwhelmed by all the studio projects I’ve got going on and chose to do something irrelevant.)

I needed to mix up more of my go-to shino, “Dolly’s Russian Hotel” and decided to mix up a couple 100g test batches as well, subbing the Redart for Newman (1.12) and Barnard (1.11).

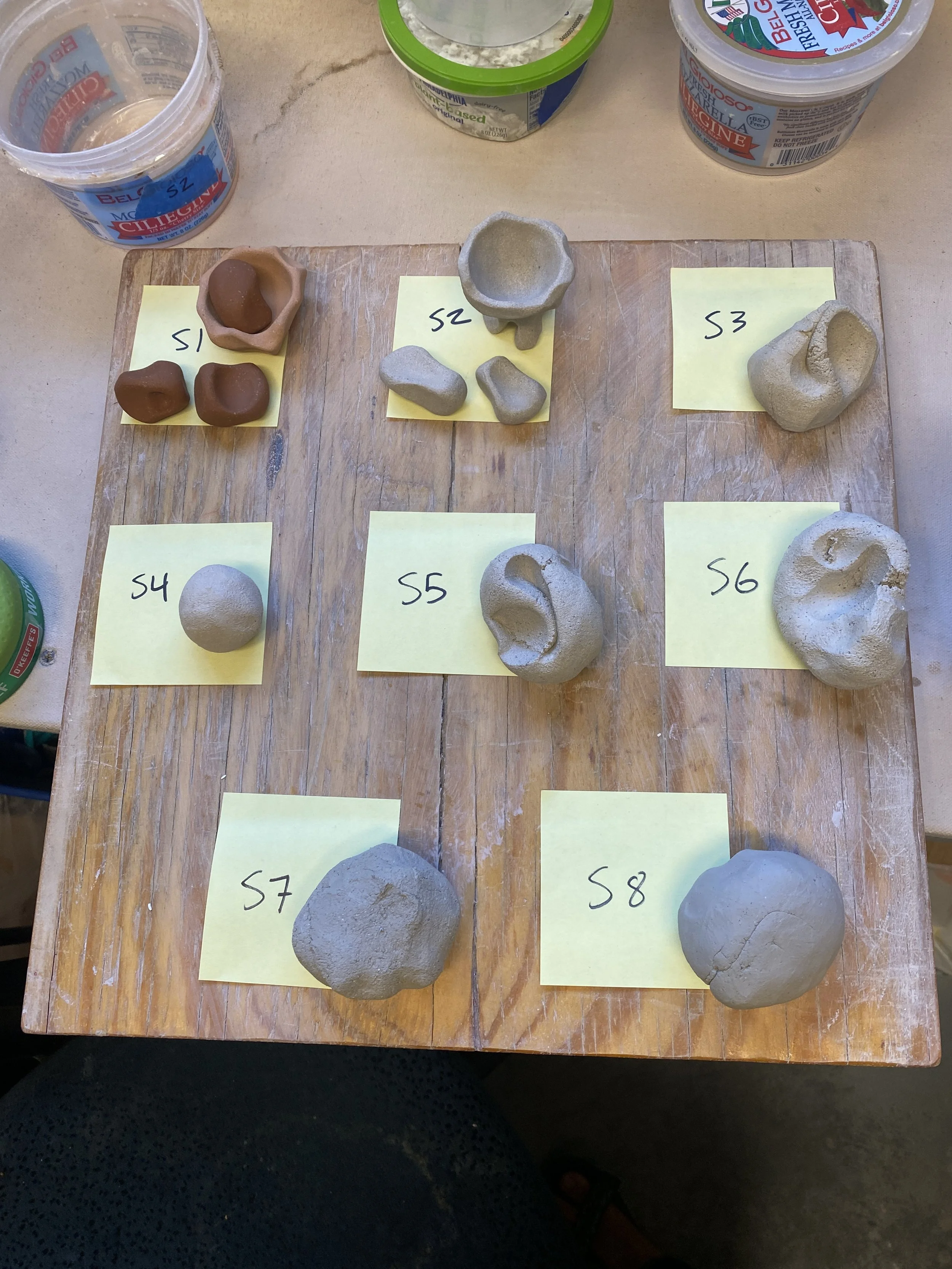

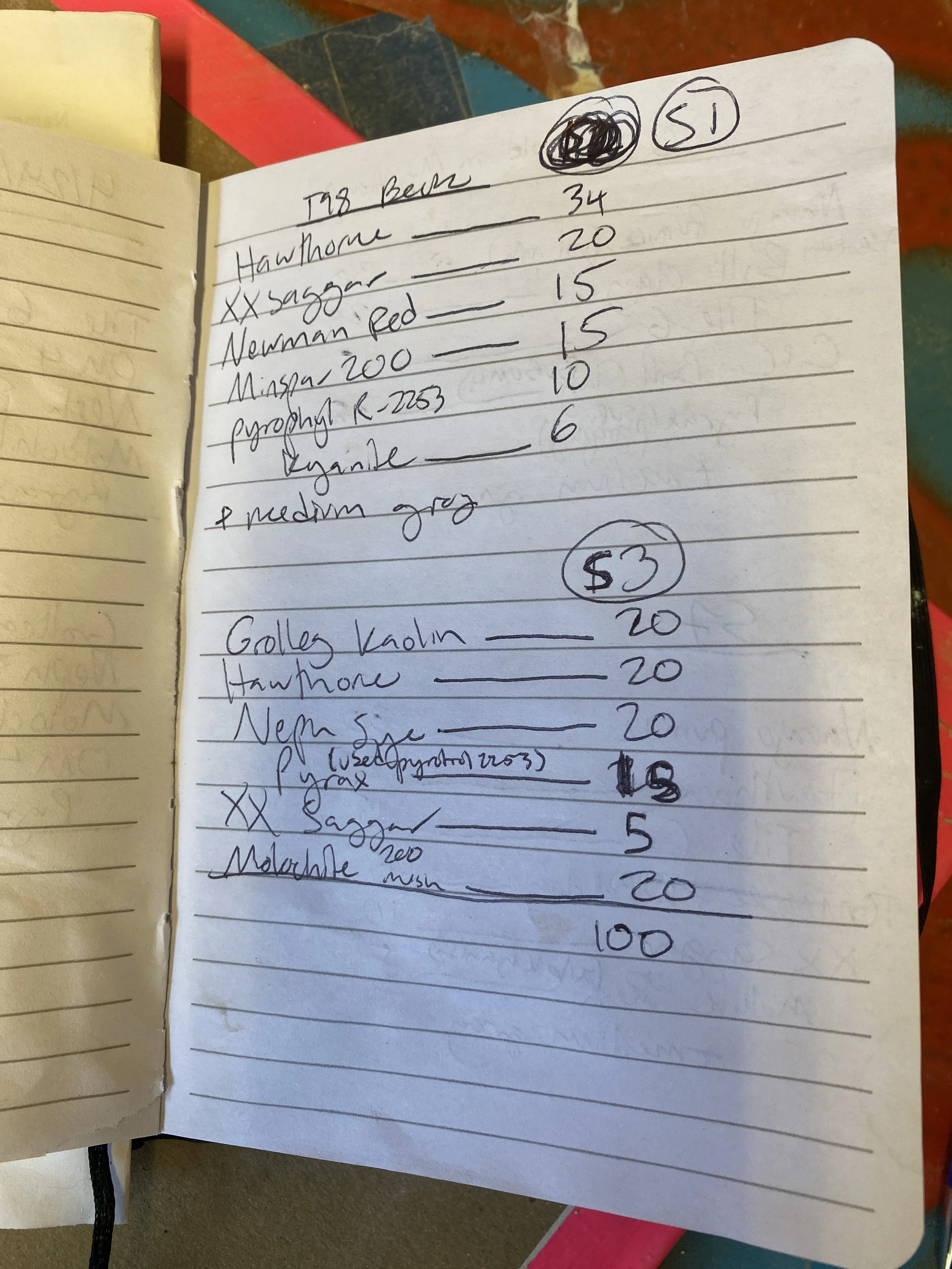

I also made tiny test batches of 8 different high-fire stonewares that I plan to put in the wood-firing; I’m trying to find a base recipe to play around with when I’m at Cobb. Most of these recipes are Casey Beck’s, and two (S7 + S8) are ones that I saved from an NCECA presentation on the effects of pumice/volcanic ash in stoneware.

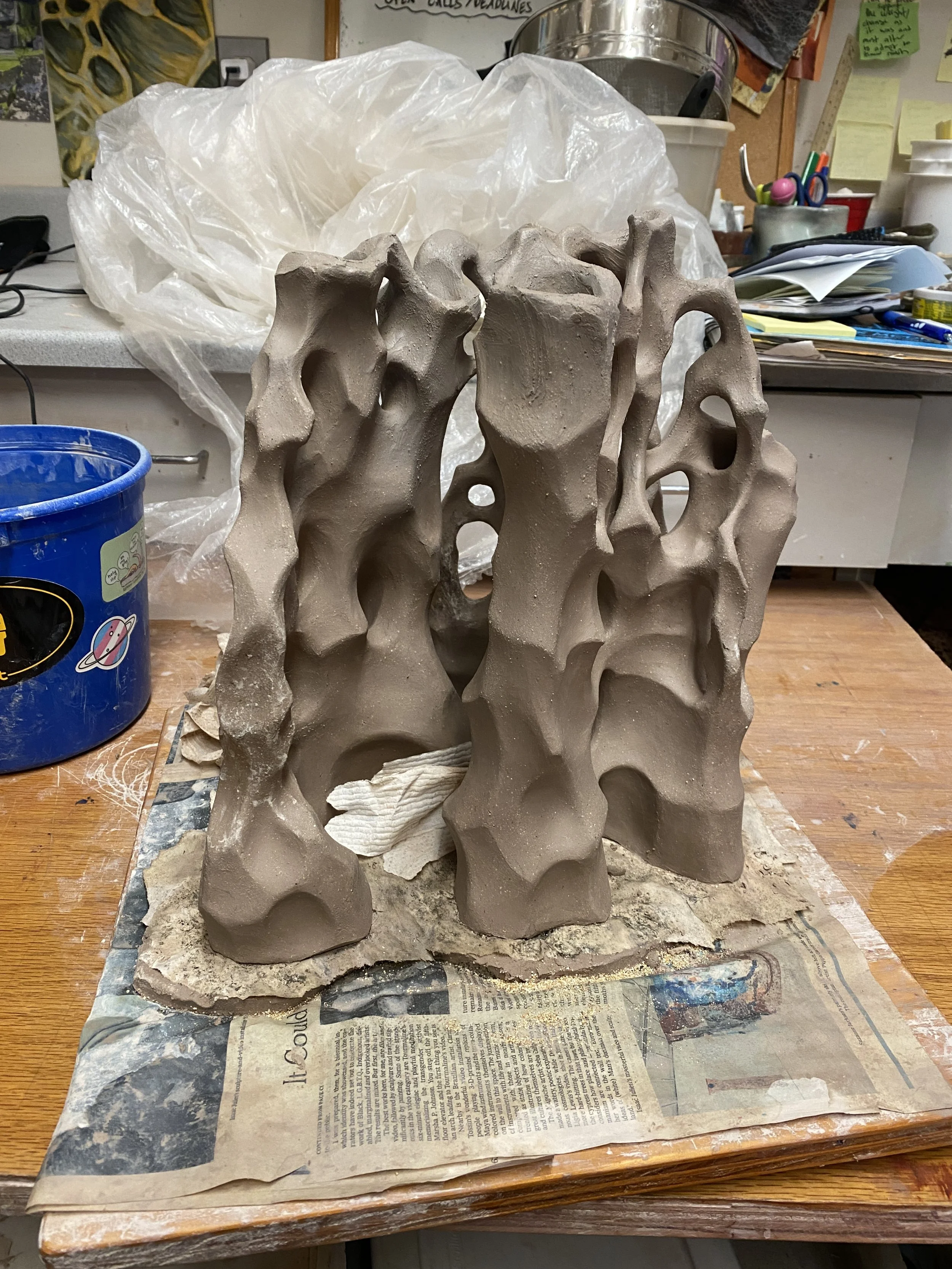

Finally, I spent a couple hours working on the sculpture I was working on prior to my trip. I hope to finish it by this coming Wednesday in time for a soda firing I have planned next week.